LED驱动电源在线式自动老化系统

在线式电源自动老化系统概述

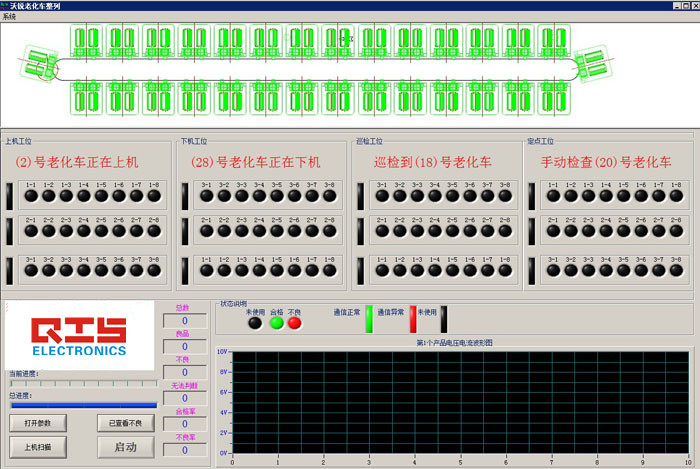

LED驱动电源在线式自动老化系统是沿用业内成熟的环形成品自动老化线体结构模式,结合我公司程控式电子负载模块技术而创新的一种在线监控LED驱动电源成品(半成品)老化系统。该系统采用电脑操作,可由PC机对各个区域工作状况进行监控与警示,设定其工作的启停,并记录相关数据,作统计分析。其负载主体采用CC/CV/LED模式程控电子负载,通过软件监控系统对负载本体工作模式、加载方式、电压、电流监控等功能进行设定和数据传输。节省传统负载车产品装载周期,及产品物流过程与老化人员数量,降低成本,并可确保老化相关数据的可追溯性、稳定性与可控性。

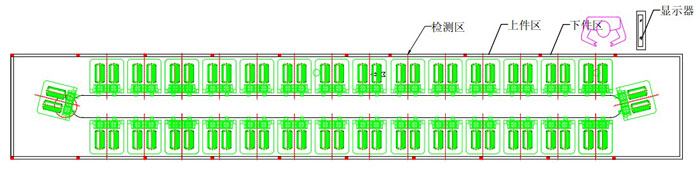

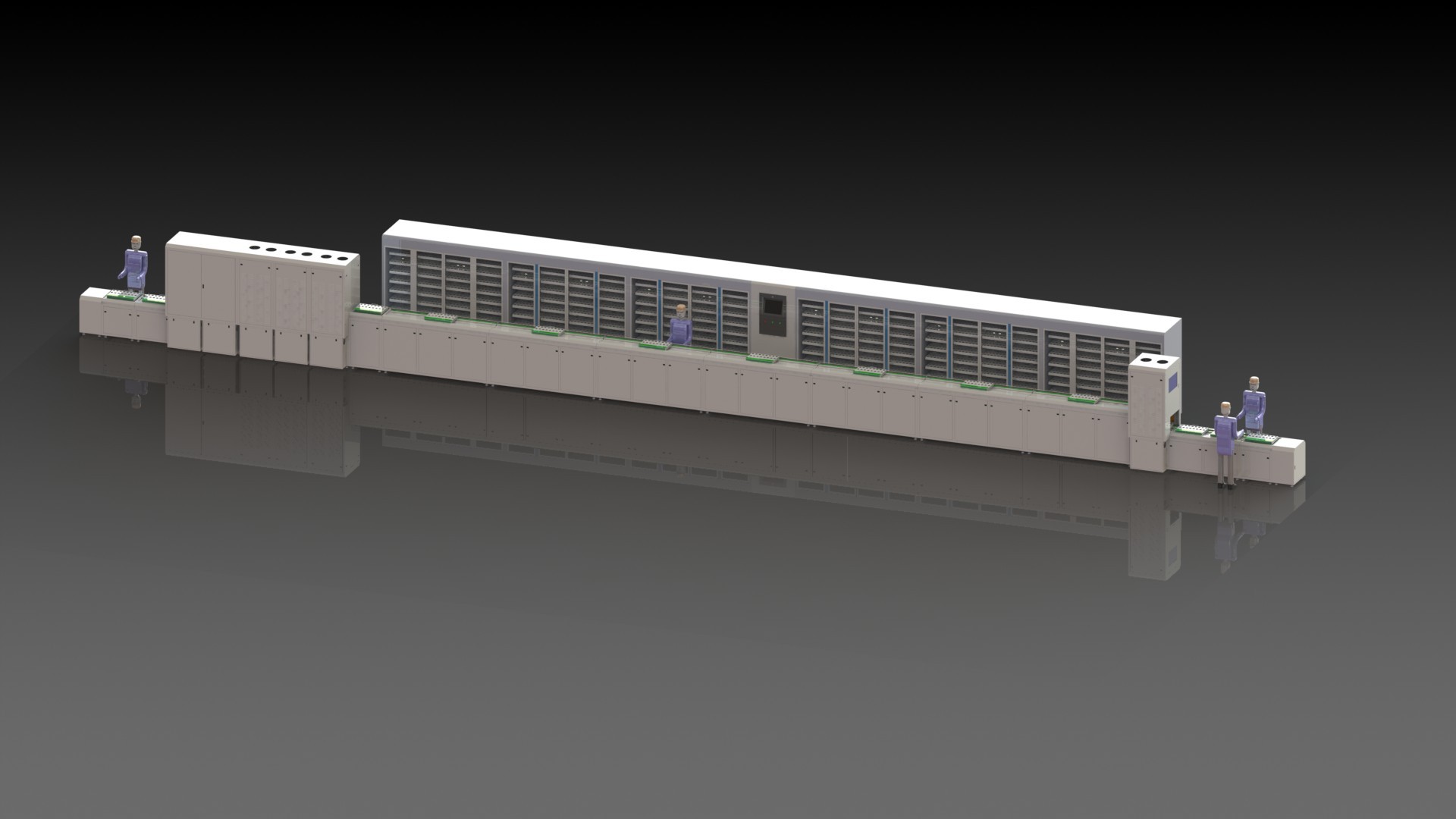

在线式电源自动老化系统主要由老化输送线体、工装小台车、负载模组、控制监控系统、电控系统、机架及排风恒温系统等组成。

工作流程:工装栈板---上机--- 检测---老化输送线---老化状态监控---下机---重上机(如此循环)

(传输线体示意图一)

控制监控系统部分:

2、自动测试/老化设备

2、自动测试/老化设备

ATE/Burn-in test equipment series

◇适用于各类充电器、适配器等电源产品的在线自动测试以及老化

◇Aplicable to all kinds of chargers/adapters and other power products for online automatic test and burn-in test

1.采用全自动作业方式,每小时产能>1500PCS 1.Using automatic operation mode,hourly capacity is greater than 1500 pcs

2.全自动作业方式,相对人工更加稳定可靠 2.Automatic operation mode is more stable and reliable than manual work

3.具有自动高压测试、ATE测试、老化测试等 3.Equipped with automatic hi-pot test,ATE test,burn-in test and so on

4.单元式设计,可根据客户需要进行具体配置 4.Modular design,which is able to make specific configuration according to user needs

5.节省劳动力,减轻劳动强度 5.Save labour and reduce labor intensity

6.产品老化与测试一体化,无需周转,提升自动化程度 6.Integrate product burn-in with test without any turnover,improving the automatic degree

7.多个测试站整合,节省空间,老化过程实时监控 7.Integrate multiple test stations to save space,Monitor burn-in equipment in real time

8.老化测试接口独立,便于后续维护,节约维护成本 8.Burn-in test interface is independent,easy for follow-up maintenance,and saves maintenance cost

9.通用性强,DC带线或USB接口产品都可适用 9.Versatility,DC line or USB interface products are applicable

10.产品转运过程通过载体经操作员转运 10.The product transport process is carried by carrier through carrier

11.操作简单,操作员无需在高温下作业,改善作业环境 11.Operation is simple,operator does not need to work in high 只需在常温下工作 temperature,improve the working environment,only work at normal temperature

12.安装简便,整套设备采用积木组合方式,便于运输. 12.The installation is simple,and the whole set of equipment is assembled with blocds,so that it is easy to transport

性能参数 Performance parameters

一 | 设备基本信息 Basic Lnformation lf Equipment | 设备型号 Equipment Model | CB-3072 |

老化柜尺寸 Aging cabinet Size | L=2350MM,W=1000MM,H=1900MM | ||

传输线尺寸 Transmission line Size | L1960MM*W580MM*H1150MM;L1960MM*W580MM*H750MM;L600MM*W580MM*H1150MM;L600MM*W580MM*H750MM | ||

ATE柜体尺寸 ATE cabinet Size | L1200MM*W600MM*H1800MM | ||

设备材质 Equipment Material | 冷轧板喷涂+铝合金 Cold rolled plate sprayed,aluminum alloy | ||

设备重量 Equipment Weight | 老化柜体重量:600KG;线体重量:单节80KG;测试柜重量:150KG Aging cabinet weight:600KG;Line weight:single segment 80KG;Test cabinet weight:150KG | ||

二 | 老化相关信息 Related Lnformation of burn-in Line | 老化容量 Burn-in Capacity | 单个柜体:512PCS,一般配用3台-6台 Single cabinet:512pcs,usually equipped with 3units-6units |

产品功率 Product power | 3W─60W | ||

老化时间 Burn-in Time | 0-9999H | ||

老化层数 Burn-in Ply Number | 8层 | ||

移载方式 Transfer mode | 托盘载体,每个托盘16个产品位.通过操作员转运. Pallet carrier,each pallet 16 product bits,transported by operator | ||

三 | 测试相关信息 Test Station Related information | 测试工序 Test Station Types | 老化前测试、老化、耐压、终测ATE Test before aging,Burn-in,HI-POT,Final test |

测试方式 Test mode | 选配 Optional | ||

测试仪器 Test lnstruments | 选配 Optional | ||

测试数据处理 Test data processing | 选配 Optional | ||

四 | 老化温度控制 Burn-in Line Temperature Control System | 冷却循环方式 Cooling Circulation Mode | 风冷:风机+变频器+风管 Forced air cooling:fan+frequency converter+air duct |

控制范围及精度 Control scope and precision | 温度控制范围:室温-60度可调,控制精度±5度 The temperature control scope:adjustable from room temperature to 60℃.The controlprecision is ±5℃ | ||

升温速度 Temperature Rise Rate | 20分钟内可升至45度以上 Able to rise to more than 45℃ Cin 20 minutes | ||

五 | 主电气控制系统 Main Electric Control System | 保护装置 Protection Equipment | 具有单独及分段总闸开关,有独立接地保护和漏电保护装置 Possessing independent and segmentation main switches,Having independent ground protection and electricity leakage protection devices |

电力需求 Power Demands | 选配(90V、100V、110V、125V、220V、264V) Optional(90V、100V、110V、125V、220V、264V) | ||

气源需求 Air source requirements | 5--8KGF/CM3 |